In industries reliant on conveyor systems, unexpected failures can lead to significant productivity losses and high maintenance costs. Traditional inspection methods often fail to catch early signs of issues, leading to operational inefficiencies and downtime. This blog explores how advanced Conveyor Inspection Software with Predictive Monitoring addresses these challenges, ensuring seamless operations.

Challenges in Conveyor Monitoring

1. Downtime: Undetected conveyor sagging and wear lead to sudden breakdowns, causing costly operational halts.

2. Costly Maintenance: Major issues are often prioritized, while minor problems, which could prevent larger failures, go unnoticed.

3. Inefficient Monitoring: Delayed detection of conveyor issues results in extended downtime and reduced productivity.

4. Productivity Loss: Unexpected conveyor failures disrupt workflow, impacting overall production targets.

Innovative Solution: Predictive Conveyor Monitoring

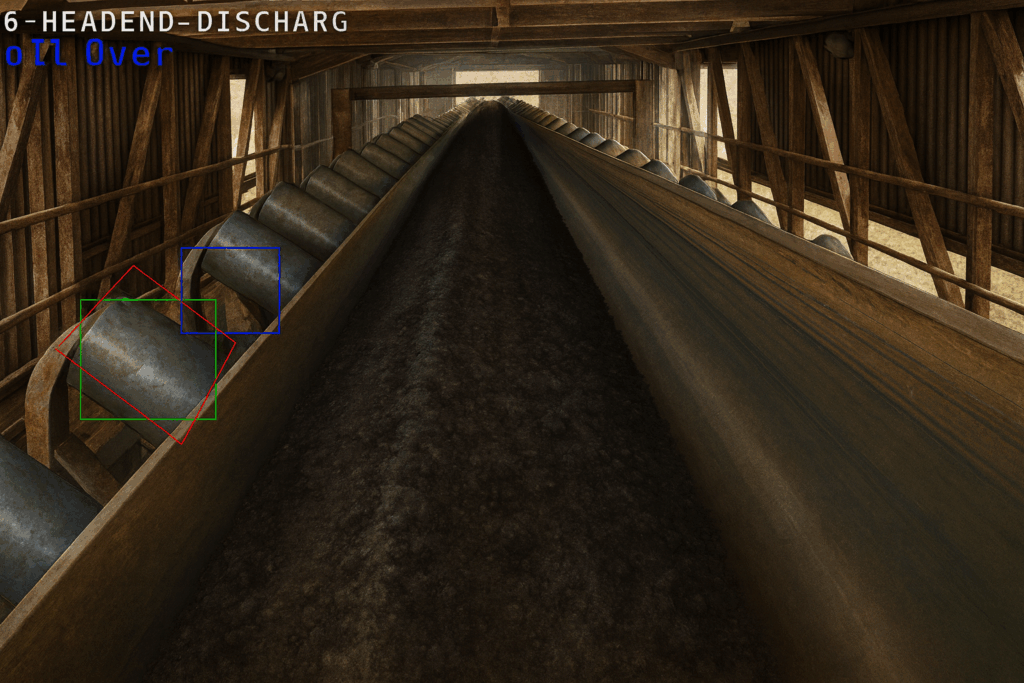

1. Camera Monitoring: Advanced cameras continuously monitor conveyor systems, detecting sagging or anomalies in real time.

2. Predictive Alerts: AI-driven predictive monitoring analyzes conveyor health, providing early warnings of potential issues.

3. Automated Alerts: The system sends timely notifications to maintenance teams, ensuring swift action to prevent breakdowns.

4. Analytics Dashboard: Comprehensive analytics tools track conveyor performance, enabling data-driven maintenance and long-term planning.

Key Benefits

1. Reduced Downtime: Real-time monitoring and predictive alerts ensure that issues are addressed before they escalate, preventing costly operational halts.

2. Cost Savings: By addressing minor issues early, the system reduces the need for expensive emergency repairs and prolongs equipment lifespan.

3. Improved Efficiency: Streamlined monitoring and maintenance processes lead to uninterrupted operations and higher productivity.

4. Enhanced Decision-Making: Actionable insights from analytics support informed maintenance scheduling and resource allocation.

Why Choose Predictive Monitoring for Conveyor Systems?

The Conveyor Inspection Software revolutionizes traditional maintenance practices with its real-time capabilities and predictive insights. Industries can now prevent unexpected failures, save costs, and optimize productivity by implementing this advanced solution. From minimizing downtime to ensuring long-term operational efficiency, the benefits are compelling.

Conclusion

Modern industries require proactive solutions to maintain seamless operations. The Conveyor Inspection Software with Predictive Monitoring is a game-changer, offering real-time insights, predictive alerts, and comprehensive analytics. Upgrade your conveyor systems today to ensure reliability, efficiency, and productivity.