In the high-paced world of metal manufacturing, precision and efficiency are paramount. The crop shear process in Hot Strip Mills (HSM) plays a crucial role in cutting metal sheets accurately. However, manual monitoring often leads to inefficiencies and errors, impacting productivity and material quality. This blog explores how DocketRun’s AI-driven solution transforms the crop shear process, delivering unparalleled precision and operational efficiency.

Challenges in Manual Crop Shear Monitoring

1. Time-Intensive and Prone to Human Errors: Manual oversight of crop shear operations requires constant vigilance and expertise. Operators face challenges in maintaining consistency, often leading to uneven cuts and material wastage.

2. Precision Issues: Inconsistent head and tail chopping of metal sheets can result in suboptimal product quality. This not only impacts customer satisfaction but also increases production costs.

3. Limited Visibility: The absence of real-time playback tools hampers decision-making. Operators often rely on guesswork or delayed feedback to make adjustments, leading to inefficiencies.

The AI-Driven Solution by DocketRun

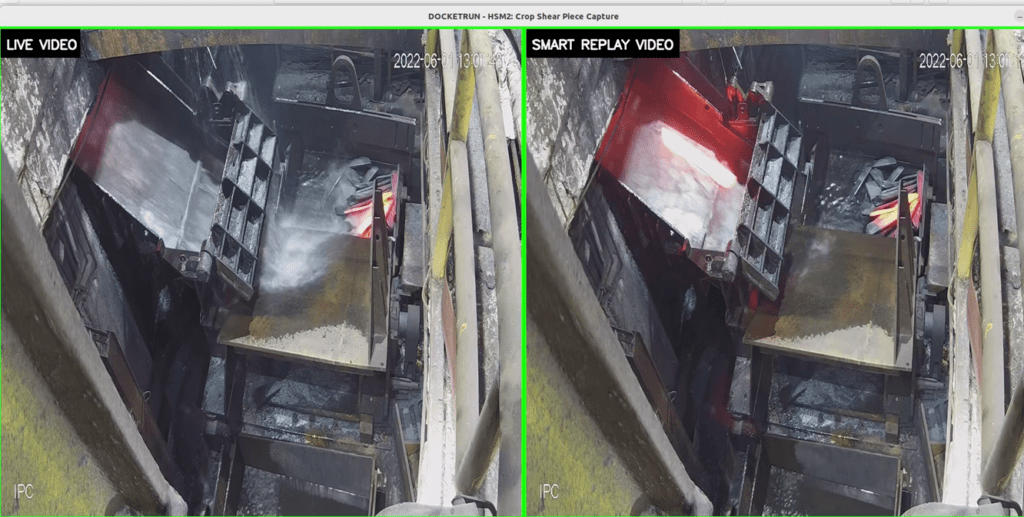

1. Intelligent Video Playback and Analysis: DocketRun’s AI System revolutionizes crop shear operations with advanced video playback and edge-cutting analysis. Operators can replay footage instantly, gaining real-time insights into the cutting process.

2. Smart Prediction Models: The system’s AI-powered algorithms optimize head and tail chopping, ensuring consistent precision across operations. These models predict cutting patterns based on historical data, minimizing errors and material wastage.

3. Real-Time Monitoring: The DocketRun AI System integrates seamlessly into existing workflows, displaying live footage on operators’ screens. This feature enables immediate feedback and facilitates swift decision-making.

Benefits of the DocketRun AI System

1. Increased Precision: With AI-driven optimization, the system enhances cutting consistency, significantly reducing material wastage and ensuring superior product quality.

2. Reduced Errors: By minimizing reliance on manual monitoring, the solution mitigates operational risks. The intelligent automation reduces the margin for human error, ensuring smooth operations.

3. Enhanced Decision-Making: Real-time playback and analysis empower operators to make informed adjustments, streamlining the entire crop shear process.

Why Choose DocketRun’s AI Solution?

DocketRun’s commitment to innovation and excellence makes it the ideal partner for modernizing HSM crop shear operations. The AI System is designed to enhance productivity, safety, and quality while reducing operational inefficiencies. By integrating intelligent technologies into the manufacturing process, DocketRun ensures businesses stay ahead in the competitive market.

Final Thoughts

The challenges of manual monitoring in HSM crop shear operations are now a thing of the past. With DocketRun’s AI System, manufacturers can achieve unprecedented precision, efficiency, and reliability. Embrace the future of manufacturing with AI-driven solutions and take your operations to the next level.