Manual data entry is a bottleneck in industrial operations, introducing inefficiencies and errors. The lack of automated integration with Programmable Logic Controllers (PLCs) further compounds operational challenges. This blog explores a robust Optical Character Recognition (OCR) system designed to automate data extraction and seamlessly integrate with PLCs for enhanced productivity.

Challenges in Manual Data Handling

1. Error-Prone Data Entry: Relying on manual processes to input data from pellet bars and transfer cars increases the likelihood of mistakes, impacting operational accuracy.

2. Inefficient Processes: Manual workflows slow down operations, creating delays in critical decision-making and process execution.

3. Lack of Automation with PLCs: The absence of automated systems for transmitting data to Siemens and other PLCs results in disjointed workflows and inefficiencies.

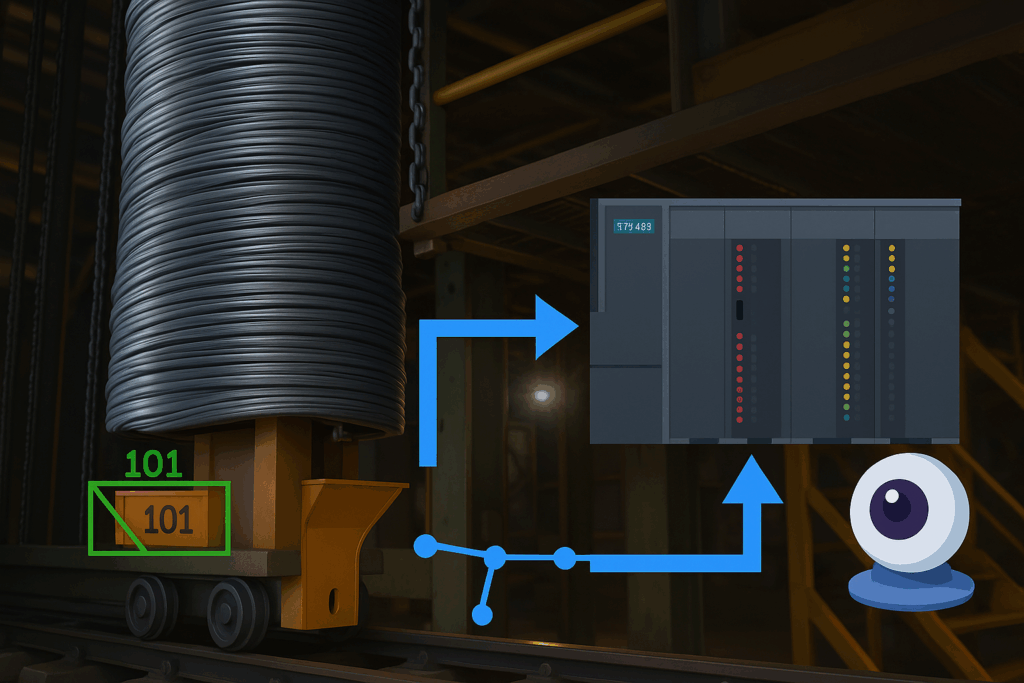

Innovative Solution: OCR System with PLC Integration

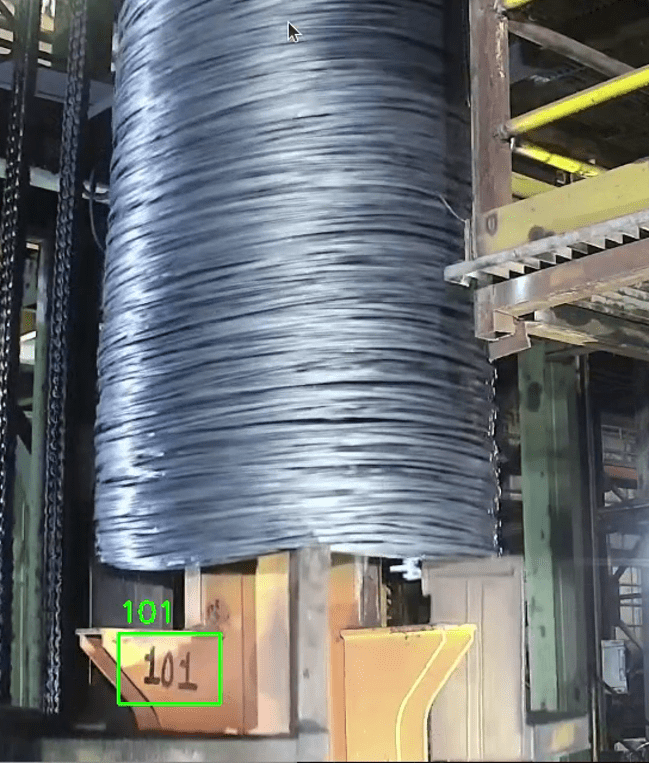

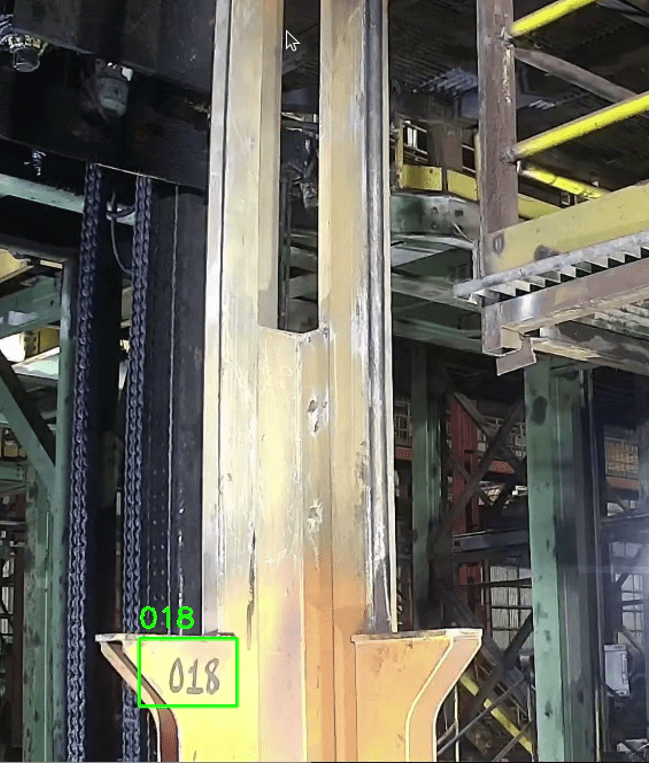

1. OCR Detection:

- Extracts alphanumeric data directly from pellet bars and transfer cars using advanced OCR technology.

- Ensures high accuracy in identifying numbers and characters for seamless data handling.

2. Real-Time PLC Integration:

- Automatically sends extracted data to Siemens and other PLCs in real time.

- Enables direct communication between the OCR system and industrial control systems for streamlined operations.

3. Utilizes Existing Cameras:

- Integrates with current camera infrastructure, eliminating the need for new hardware.

- Offers a cost-effective solution without compromising efficiency.

Key Benefits

1. Accuracy:

- Automates data extraction to eliminate manual errors.

- Enhances operational precision by ensuring reliable data input.

2. Efficiency:

- Streamlines processes by automating the identification and transmission of data.

- Reduces delays, allowing for faster decision-making and improved productivity.

3. Cost-Effectiveness:

- Leverages existing camera systems, minimizing additional investment.

- Reduces labor costs associated with manual data entry.

4. Scalability:

- Easily deployable across multiple departments and facilities.

- Adaptable to various industrial applications requiring PLC integration.

Why Adopt an OCR System for PLC Integration?

The OCR System for PLC Integration transforms traditional manual workflows into automated, high-precision processes. By leveraging existing infrastructure and ensuring real-time communication with PLCs, the system provides a scalable, cost-effective solution for industrial automation. This approach not only improves efficiency but also enhances data reliability and operational continuity.

Conclusion

Industrial operations demand accuracy, efficiency, and scalability. The OCR System for PLC Integration meets these needs by automating data handling and enabling seamless communication with PLCs. Embrace this innovative technology to enhance productivity and drive operational excellence in your organization.