In the Steel Plant, the slag discharging process has long been a challenging operation. Eight massive hoppers handle slag every day, while trucks line up beneath them to collect the material. Amidst dense smoke, heat, and noise, operators have traditionally relied on manual signaling and observation to coordinate slag loading—a method prone to delays, uneven distribution, and safety risks.

But change is here. Docketrun’s smart AI-based automation solution is revolutionizing this process, bringing precision, speed, and safety to an area once dominated by uncertainty.

The Challenge: Manual Operations in a Demanding Environment

Slag handling is no simple task. Each truck must be positioned correctly under the hopper, the right amount of slag needs to be discharged, and this cycle must repeat seamlessly across multiple heaps. Previously, operators manually guided drivers and triggered discharges based on judgment alone.

The drawbacks were clear:

• Safety concerns due to dense smoke and manual intervention

• Inefficient loading, with some heaps overfilled and others underutilized

• Delays and downtime, as coordination took time and precision was often lacking

In a fast-paced industrial environment, these inefficiencies added up, creating bottlenecks and risks.

The Solution: Docketrun’s Smart AI Automation

Docketrun has transformed slag handling with an AI-powered, fully automated solution that minimizes human intervention while maximizing efficiency.

Here’s how it works:

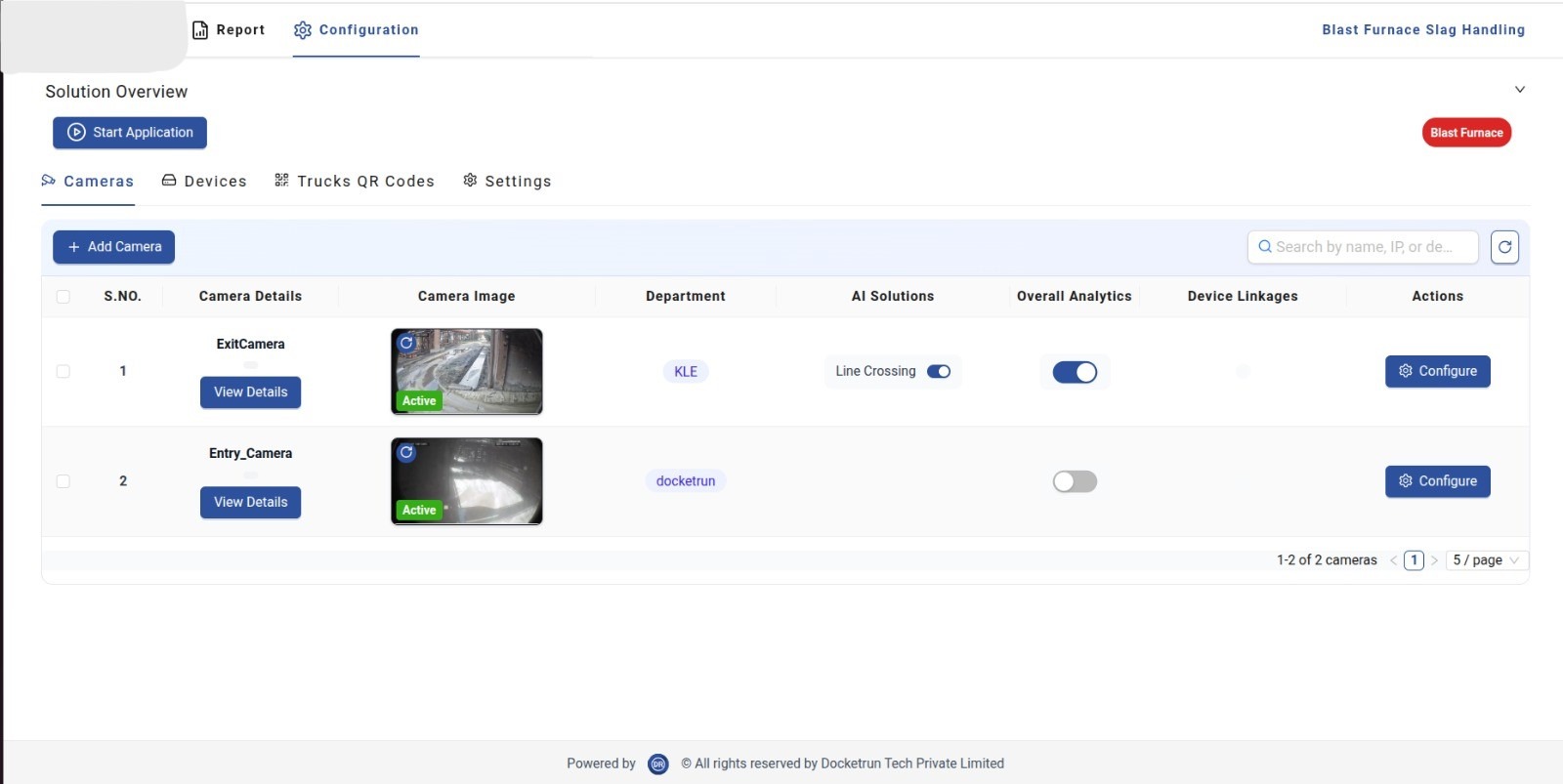

Real-Time Monitoring – Authorised personnel monitor the process directly from the control room through an integrated display system.

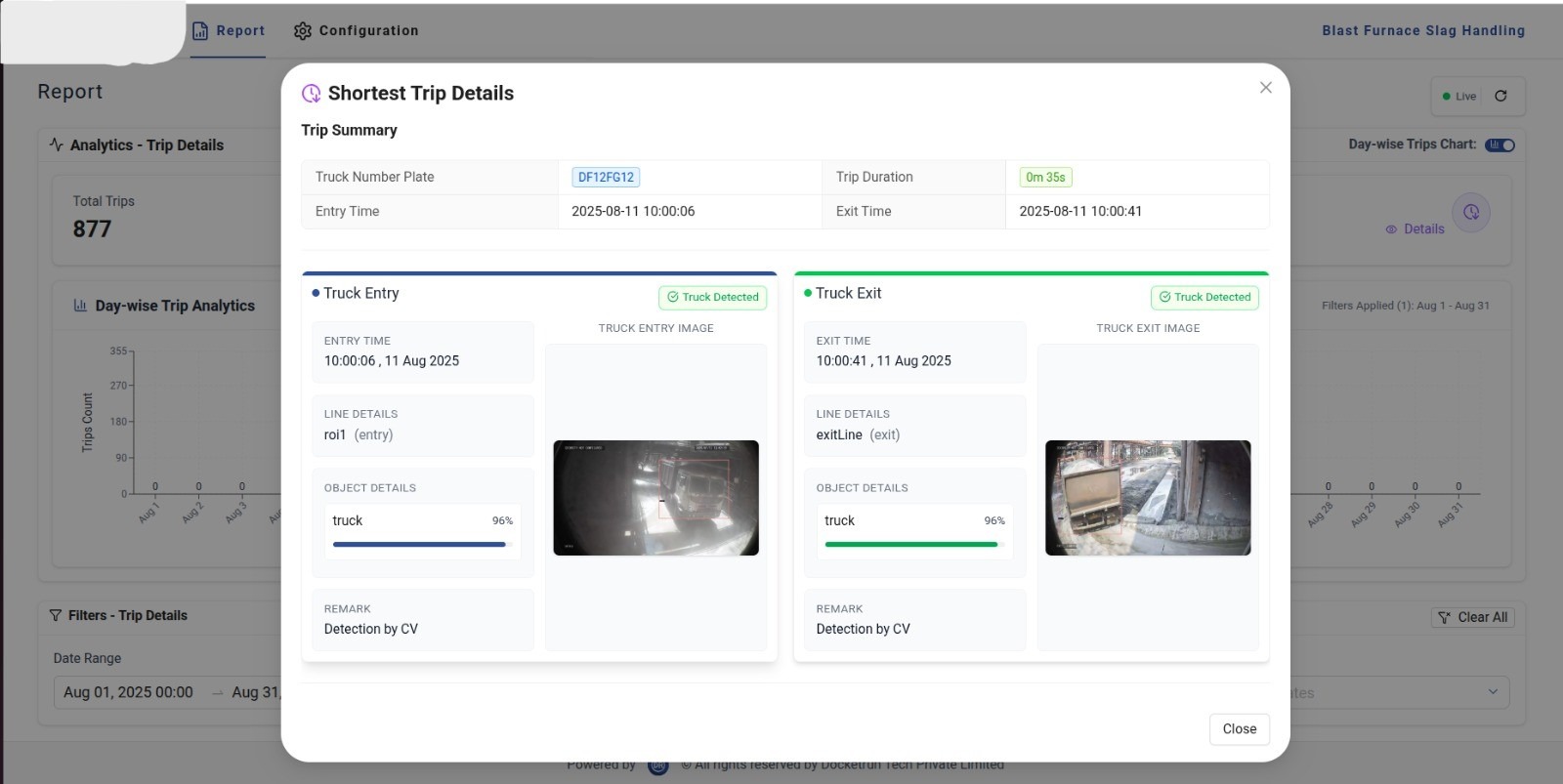

Truck Recognition – As a truck enters the discharge area, the system automatically captures its licence plate, verifying and granting it access.

Guided Positioning – Wall markings guide the truck driver to the exact position under the hopper, ensuring precision without guesswork.

Automatic Discharge – Once aligned, the system triggers a relay to start slag discharge automatically. Manual signaling is no longer needed.

Optimized Loading – The system forms five evenly distributed heaps in the truck, optimizing loading and reducing wastage.

Completion Alert – When the final heap is formed, a long alarm signals the driver to proceed to the unloading area.

This cycle repeats smoothly, truck after truck, without interruptions.

The Benefits: Efficiency Meets Safety

By automating slag discharging, Steel Plant has unlocked multiple benefits:

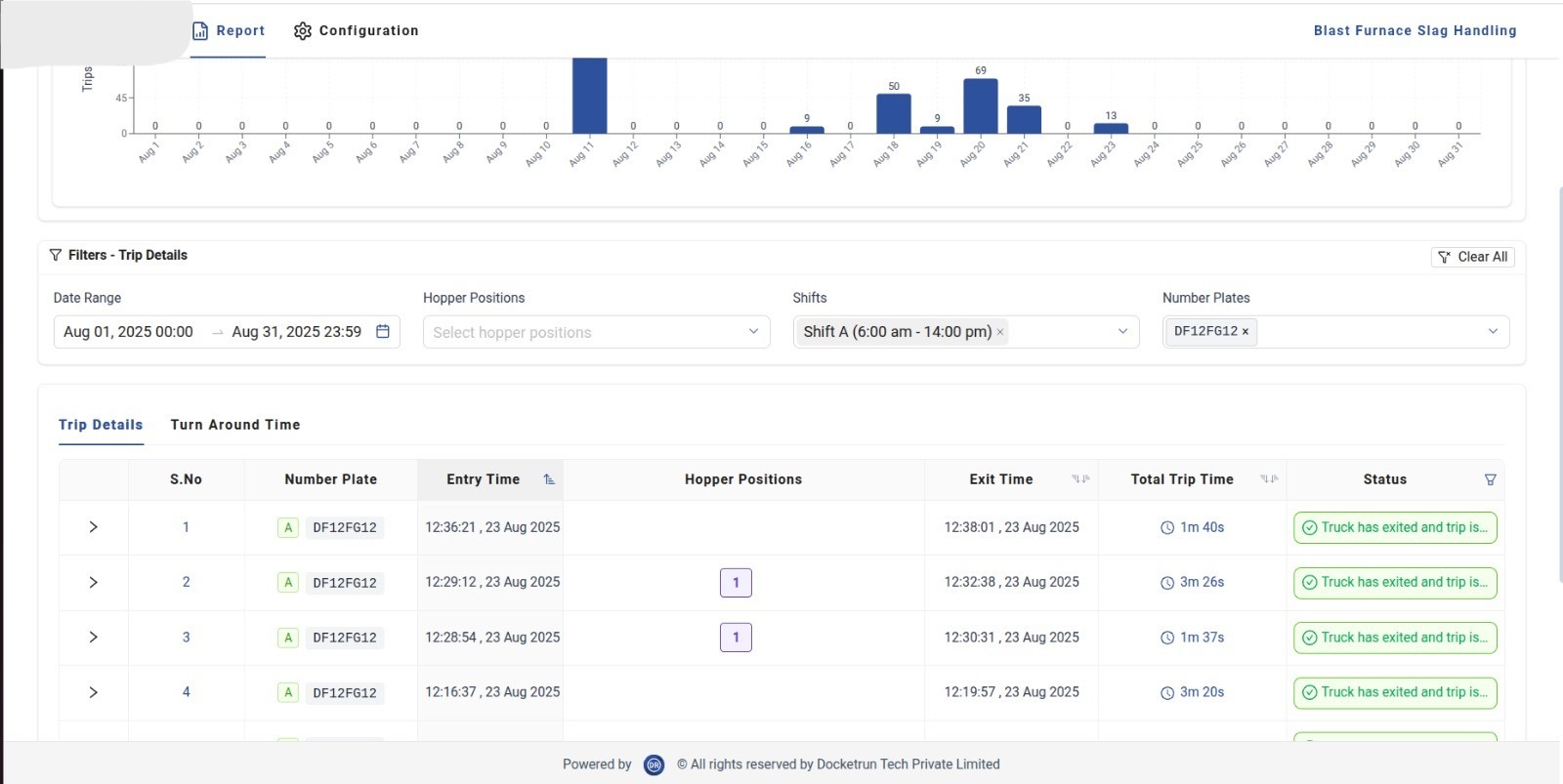

• Improved Efficiency: Faster turnaround times with seamless truck loading.

• Enhanced Safety: Reduced manual involvement in hazardous zones.

• Optimized Distribution: Even slag heaps ensure maximum utilization of truck capacity.

• Real-Time Control: Supervisors can monitor operations remotely.

• Reduced Delays: Automated triggers eliminate human error and miscommunication.

A Step towards the Future

Docketrun’s AI-driven automation is more than just a solution—it’s a glimpse into the future of smart steelmaking. By digitizing and automating one of the most challenging parts of the blast furnace workflow, Steel Plant sets a new benchmark for safety and efficiency in heavy industry.

As industries embrace AI-powered automation, processes that were once labor-intensive and risky are being reimagined as streamlined, safe, and precise operations. Slag handling at Steel Plant is a shining example of this transformation.