Don’t just Imagine AIoT Experience it with Docketrun

Gain an insight into how Docketrun’s AI-powered solutions are revolutionizing the operations of heavy industries.

Gain an insight into how Docketrun’s AI-powered solutions are revolutionizing the operations of heavy industries.

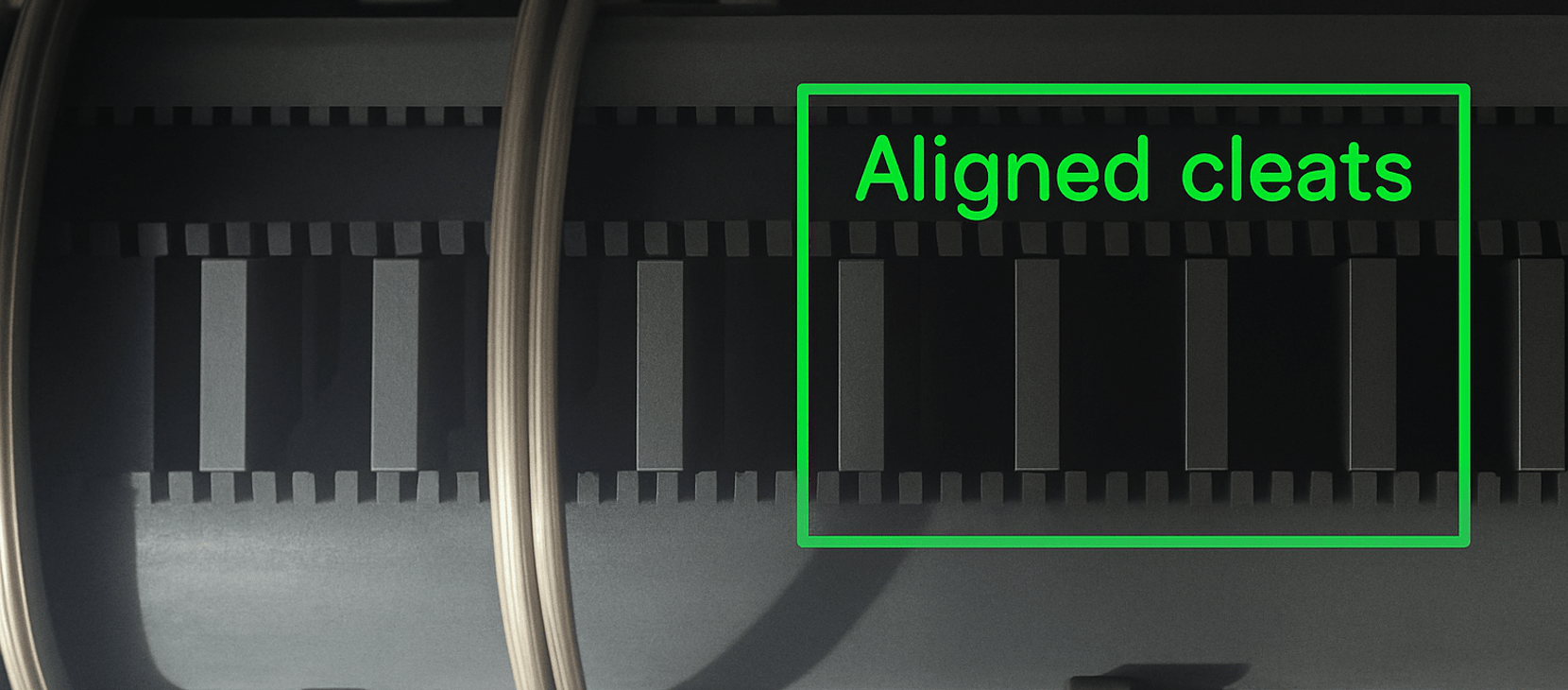

Conveyor systems in heavy industrial environments often face issues like non-linear side walls and misaligned cleats. These structural irregularities cause frequent material spillage and disrupt the flow, leading to increased maintenance efforts, unplanned downtimes, and reduced operational efficiency.

DocketRun’s Smart Conveyor Inspection System leverages AI-driven video analytics to:

Industrial environments often rely on manual fire monitoring, which lacks real-time responsiveness. Human oversight in complex facilities can delay critical action, and traditional systems fail to provide comprehensive data for fire risk assessment.

DocketRun’s Fire Detection System uses advanced AI and video analytics to:

Manual dust monitoring in industrial environments is time-consuming and unreliable, often leading to inconsistent observation and limited visibility into dust trends or root causes.

DocketRun's Automated Dust Monitoring System leverages strategically placed cameras and AI-powered analytics to:

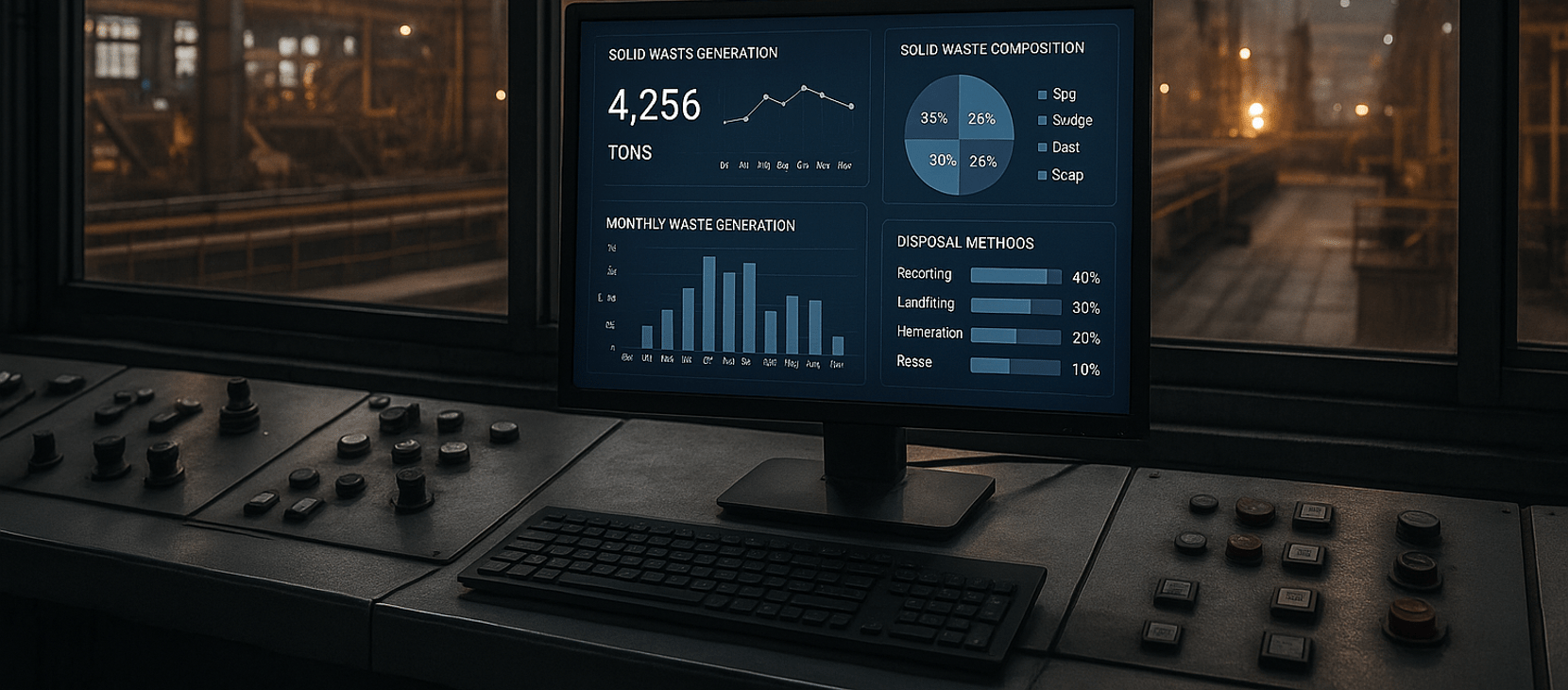

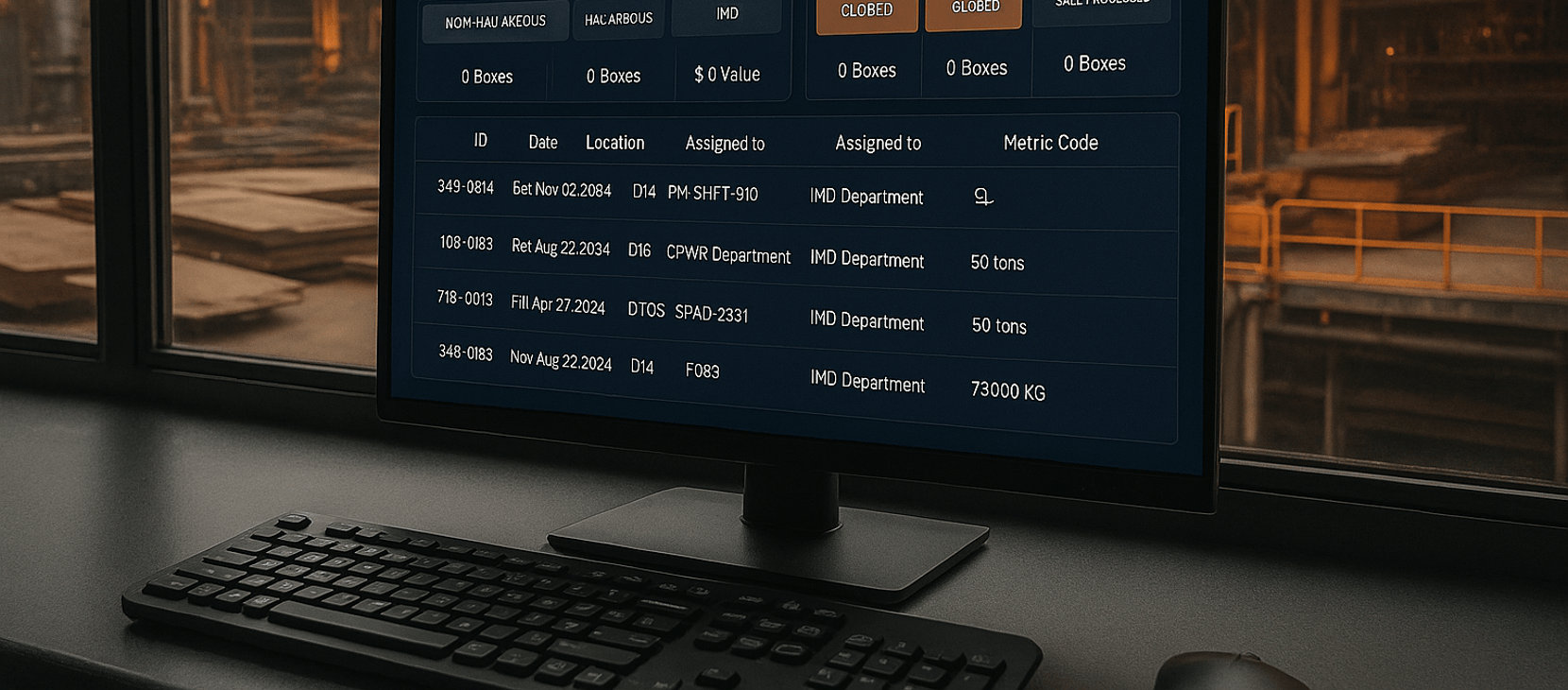

Steel plants struggle with inefficient tracking of solid waste, missed opportunities for internal reuse, and a lack of actionable analytics. Manual processes lead to delays, data gaps, and limited visibility into waste movement and potential.

DocketRun's AI-powered Waste Inventory Management System:

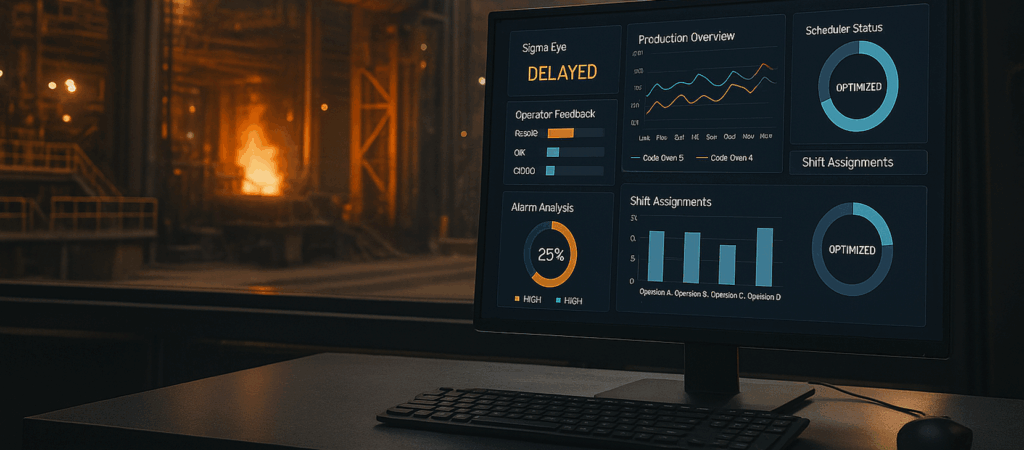

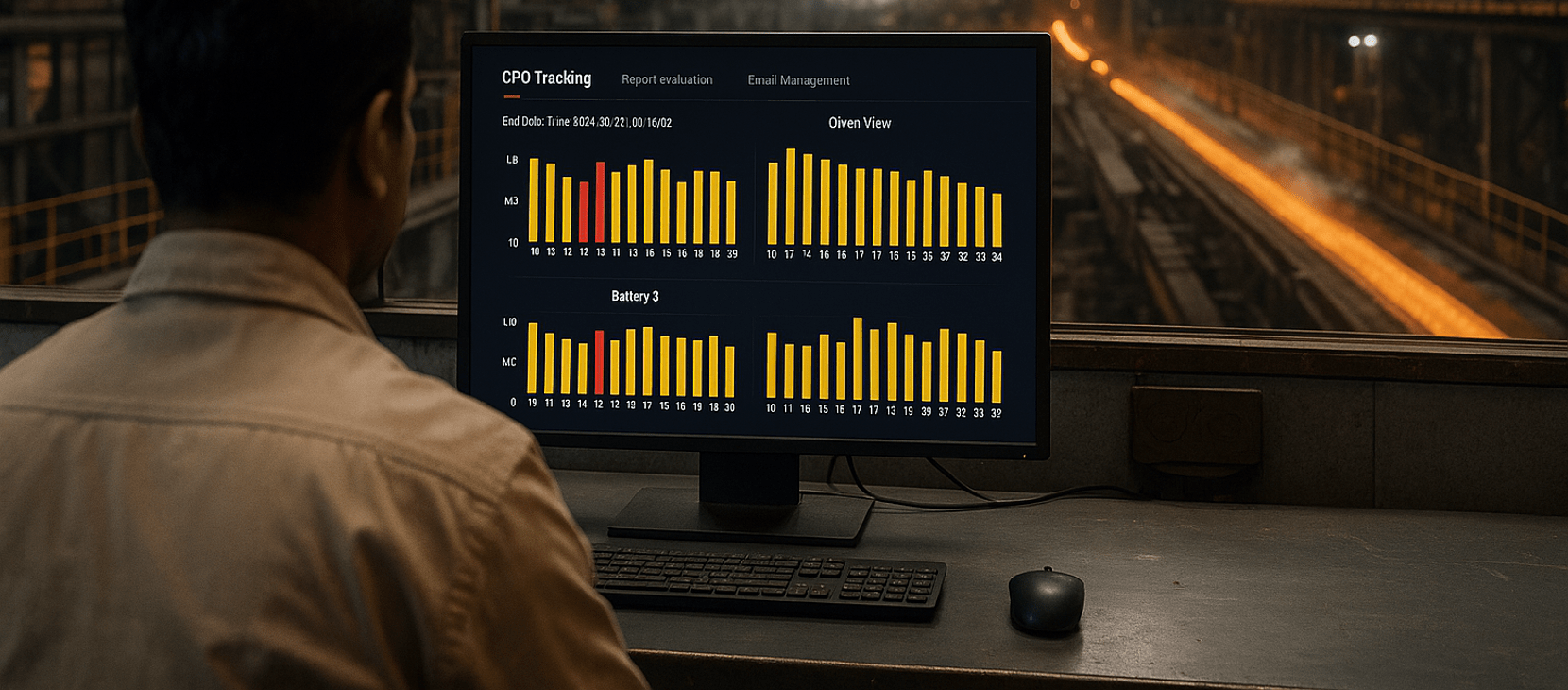

Manual data handling in Sigma Eye and scheduling tools causes delays in decision-making, production inconsistencies, and increased risk of human error—especially across complex units like coke ovens.

DocketRun's intelligent upgrades to decision and scheduling systems:

Inspecting areas like roofs and pipelines using traditional methods, such as climbing or scaffolding, is risky, time-consuming, and limits the scope for a thorough inspection.

DocketRun's AI-powered Video Analytics solution:

Evaluating employees working at heights with safety gear and permits is challenging. The absence of progress records and SOP visibility compounds this, making remote monitoring of shutdowns and critical tasks difficult.

DocketRun's Smart 4G-enabled camera with rechargeable battery and solar-enabled system

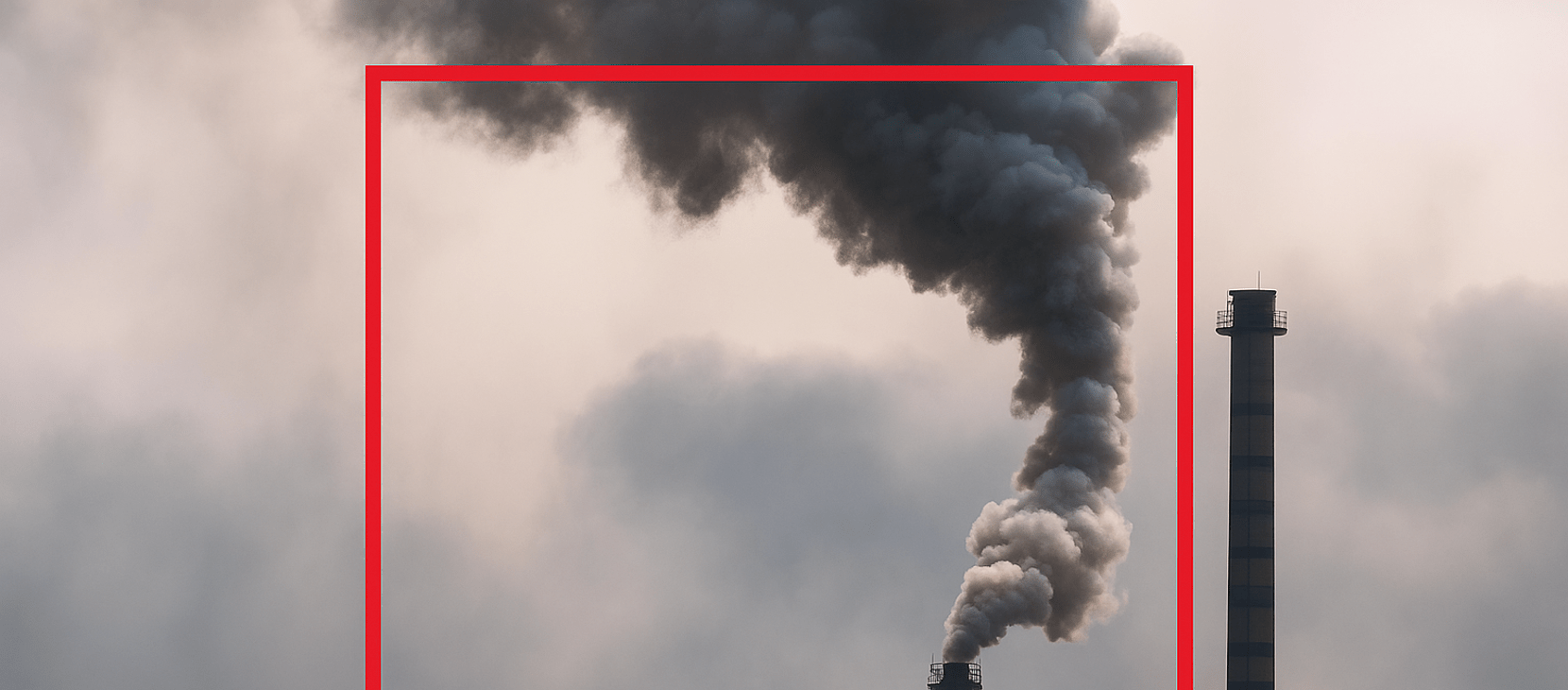

Monitoring chimney areas for fire, smoke, and thermal anomalies is critical due to the risk of equipment-induced fires or worker injury. Avoiding this costly and potentially fatal mistake must be avoided.

DocketRun's automated 24*7 monitoring system will help you:

During the SLAB Movement via railway track, observing employees' movements and adhering to standard operating procedures (SOPs) is challenging when done manually.

DocketRun's advanced automated system will help you:

The challenge lies in effectively monitoring the metal edge-cutting process (Head and Tail) of metal sheets at the HSM. Workers struggle to oversee the metal chopping, necessitating a solution for smart-play video implementation.

Implement DocketRun AI System to:

The steel industry struggles to monitor personnel in cellar areas due to the absence of suitable camera installations and the inefficiency of manual tracking. This results in costly and time-consuming processes.

DocketRun's cutting-edge system for location-based real-time workflow and people tracking.

Frequent and multiple foreign materials on the conveyor belt result in breakdowns. This disruption halts the entire production system, causing significant delays in manufacturing and diminishing overall productivity.

DocketRun's advanced Camera Video Analytics:

Due to the steel plant's vast size and low visibility, nighttime patrols struggle to ensure security guards and vehicles perform their duties effectively. This oversight challenge increases the risk of security breaches and threatens the safety of employees, visitors, and assets.

Leverage DocketRun's Smart GPS Rechargeable Module with Web Application and Mobile App:

Unauthorized entry into a steel factory's restricted areas may result in safety hazards, production disruptions, and equipment damage. Implementing access control systems, physical barriers, and comprehensive training are vital solutions to mitigate unauthorized entry.

DocketRun's locking biometric systems will help you:

Identifying coil defects in HSM2 is challenging due to diverse issues, such as edge cracks, bursts, damage, and more.

Utilize DocketRun's Edge Device to:

The strength of a welded joint is paramount in heavy industries like construction, shipbuilding, and oil & gas. Weak welds can lead to catastrophic failures, jeopardize safety, incur immense costs, and cause project delays. Traditionally, weld inspection relies on visual inspection or time-consuming ultrasonic testing, both prone to human error and inconsistencies.

DocketRun's Smart Vision System automates the detection of weld defects. The system, trained on a vast library of weld images with various defects- meticulously analyzes the weld for cracks, porosity, and other imperfections, ensuring consistent and reliable inspection.

The current manual method of maintaining the logbook for recording machine log sheets in a steel plant is inefficient, error-prone, and lacks standardization. It is impeding data analysis and decision-making processes.

DocketRun's digital system for maintaining the machine log sheet:

The current method of maintaining standard operating procedures (SOPs) and machine records via manual processes - email and paper-sticking near machinery equipment poses several challenges. These include the difficulty of effectively training new trainers during upgrades, the need for visual SOPs for enhanced operation, and communication gaps between vendors and the concerned department due to team changes.

DocketRun's advanced VSOP system:

Multiple servers capturing and storing critical data points pose a significant challenge. System failures could lead to major shutdowns, potential data loss, and overall damage to operations.

DocketRun's smart system software monitoring tool

The existing Programmable Logic Controller (PLC) system fails to indicate respective announcements to corresponding jobs, resulting in missed alerts during critical conditions.

Integrate your existing PLC system with DocketRun's smart Voice Announcement system:

Top Manufacturing Enterprises

Manufacturing Operations

with AIEmpower safer, smarter, and more efficient manufacturing processes.